Do You Have A Welding or Waterjet Project We Can Help With?

Welding + Waterjet Cutting= 1 Stop Shopping

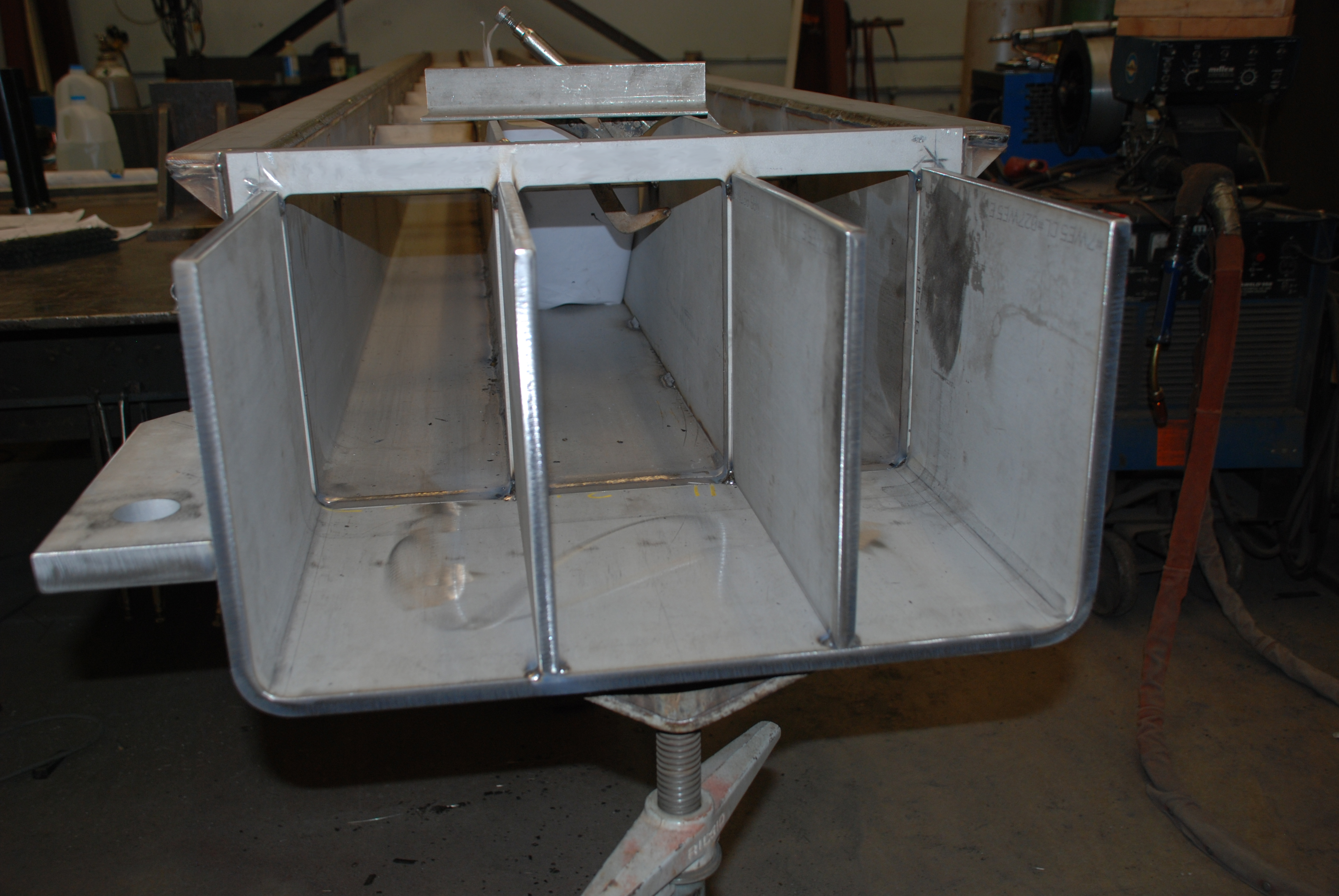

What sets Diversified apart from their peers is the diverse spectrum of capabilities. We are proficient in a wide variety of metals including Titanium, Aluminum, Cast iron and more exotic alloys such as Cooper and Bronze. We can perform heavy steel fabrication with MIG welding as well as TIG welding of exceptionally thin alloys, and some projects don’t even have to be in our facilities. We can come to you with our portable welding truck.

To add on to our diversity, we have state-of-the-art waterjet cutting services. You can have your materials purchased, cut and fabricated all in one place. And we can deliver. It’s really that easy.

Send us your quote or call for free phone consultation. 360-576-0929

We are mobile operators. When you need any kind of job in or around Vancouver/ Portland, you can count on us to be there. Whether you need a repair to get your machinery back in action, or a job that needs to be done so that you can continue your project, you can rely on Diversified Welding Works for metal fabrication and onsite repairs. DWW has come to the rescue throughout the Pacific Northwest for emergency and scheduled shut downs for over 30 years.

We are mobile operators. When you need any kind of job in or around Vancouver/ Portland, you can count on us to be there. Whether you need a repair to get your machinery back in action, or a job that needs to be done so that you can continue your project, you can rely on Diversified Welding Works for metal fabrication and onsite repairs. DWW has come to the rescue throughout the Pacific Northwest for emergency and scheduled shut downs for over 30 years.

Waterjet- A Cut Above the Rest

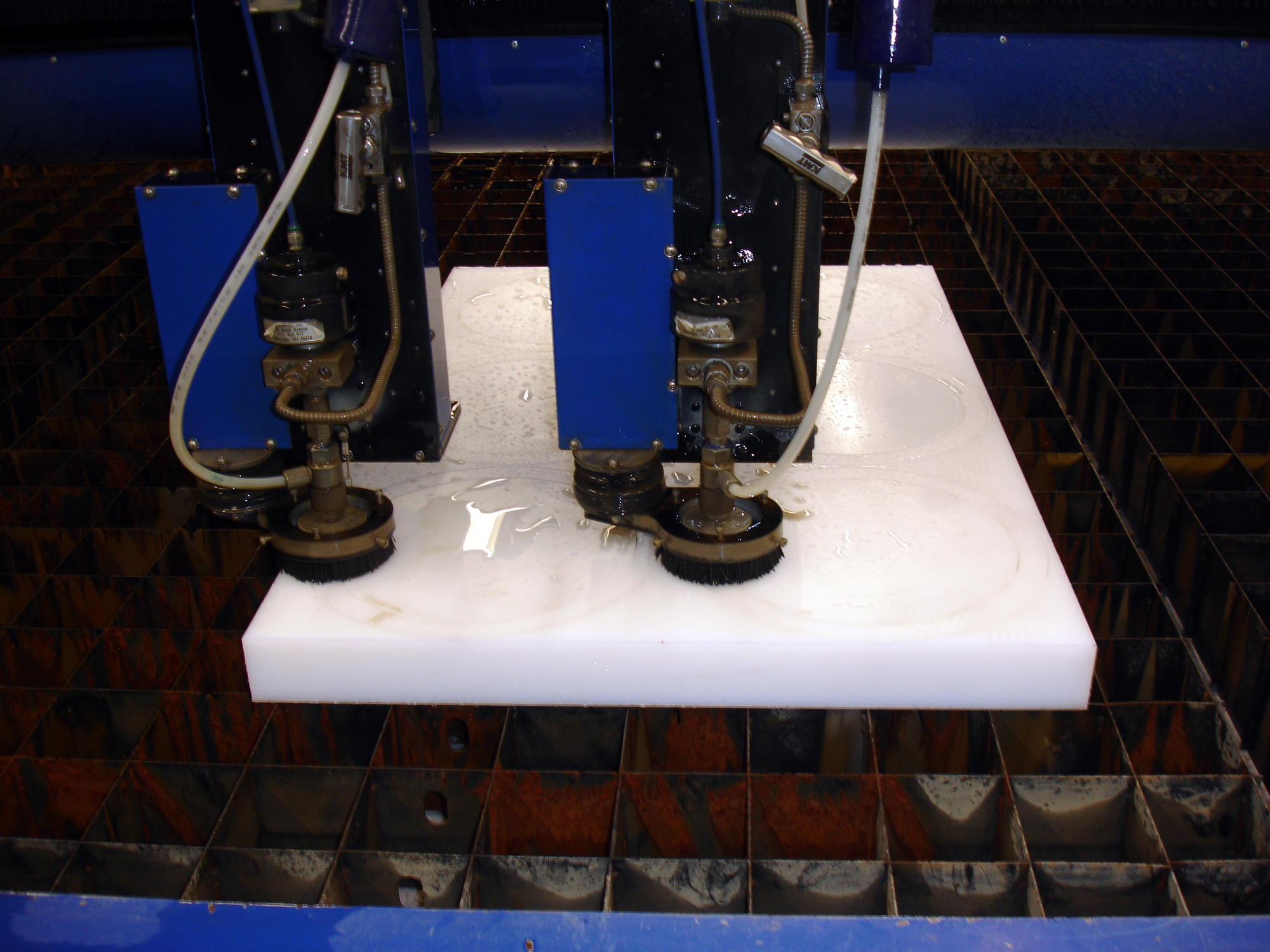

Sitting inside a plastic bottle, water may seem ordinary. Not at Diversified Welding and Waterjet, where we take it up a notch, and water cuts virtually any type of material up to 14” thick: rubber, composites, plastic, glass, marble, silicon, alloys, and even concrete. With cutting streams pressurized to 60,000 psi, the material could be solid titanium and still not put up much of a fight.

Our waterjet department turns most request for quotations in less than 24 business hours, but with a decade of experience and multi-shift capability, can possibly turn your parts out just as quickly.

The benefits of waterjet cutting vs other methods:

• Cuts almost any material

• No heat affected zone (HAZ)

• No stress added to the material during the cutting process

• No distortion or warping of materials

• Reduction of post cut machining due to precision cutting tolerances

• Burr-free cuts

• Less material waste due to utilization of nesting software that geometrically calculates part orientation.

• Cost savings by leaving the remaining material in tact to be used for another project (yours to keep)

• Ability to cut complex parts

• Provides near net shapes

Cutting tolerances vary depending on material type & thickness. Contact DWW for details

DUAL CUTTING HEADS

Greater cutting efficiency, lower production cost, twice as fast

96″ X 156″ CUTTING TABLE WITH PASS THROUGH ABILITIES

If it fits in a truck (and through the door), good odds are DWW can cut it.

VIRTUALLY ALL MATERIALS

60,000 psi cuts hardened steels to soft rubbers and everything in between.

NO HEAT-AFFECTED ZONE

Won’t harden the cut edge of metals, ideal for the aerospace industry.

PART NESTING SOFTWARE

Geometrically calculates a part orientation that will minimize material use.

INGENIOUS STAFF

Our talented Waterjet Team has the ingenuity to assist you in finding your project solutions.

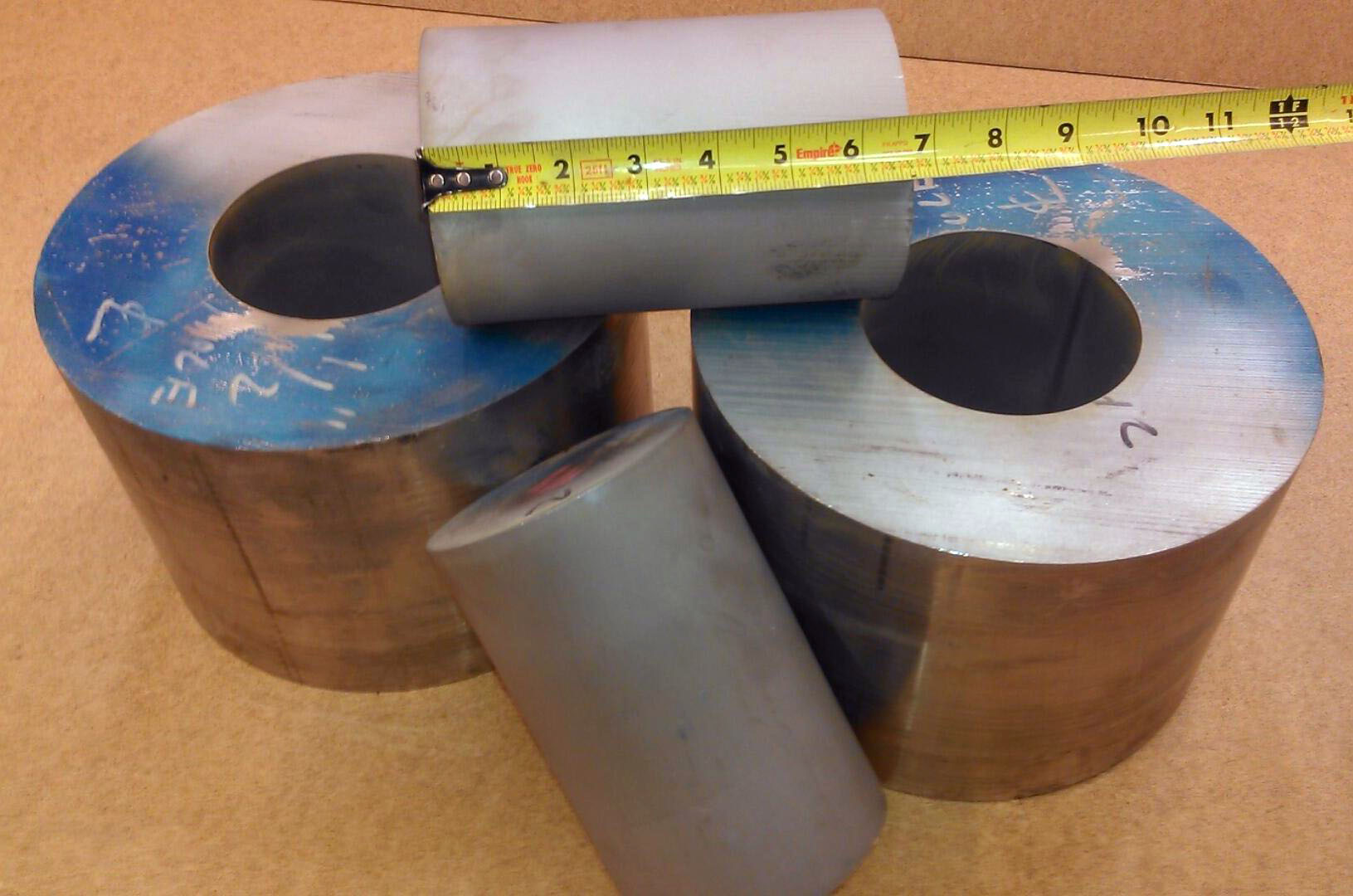

7″ Metal Waterjet Cut

7″ Metal Waterjet CutExamples of materials cut by DWW:

Acrylic

Aluminum

Armor Plating

Brass

Bronze

Carbon Steel

Ceramics

Composites

Copper

Farraloy

Foams

Glass (except tempered)

Hastelloy

Kevlar

Marble

Phenolic

Plastics

Rubber

Silicone

Stainless Steel

Titanium

Tool Steel

UHMW

Wood

We do the projects “not just any welder” can or should do.

Since 1993, DWW has been the industrial weld repair and metallurgic expertise resource for the Pacific Northwest. We partner with numerous CNC machine shops to come up with the best repair or new manufacture for Industrial and Commercial applications.

Examples of Industries We Serve:

Windmill Turbine

Pulp & Paper

Aerospace

Steel Mills

Logging & Lumber

Machine shop, metals

Metal Distributors

Food Service

Construction, certified welding

Crane Wheels- rebuild, H-2

Antique Rejuvenators

Plastics, injection mold repair

Mairtime

Grate Industrial Repair

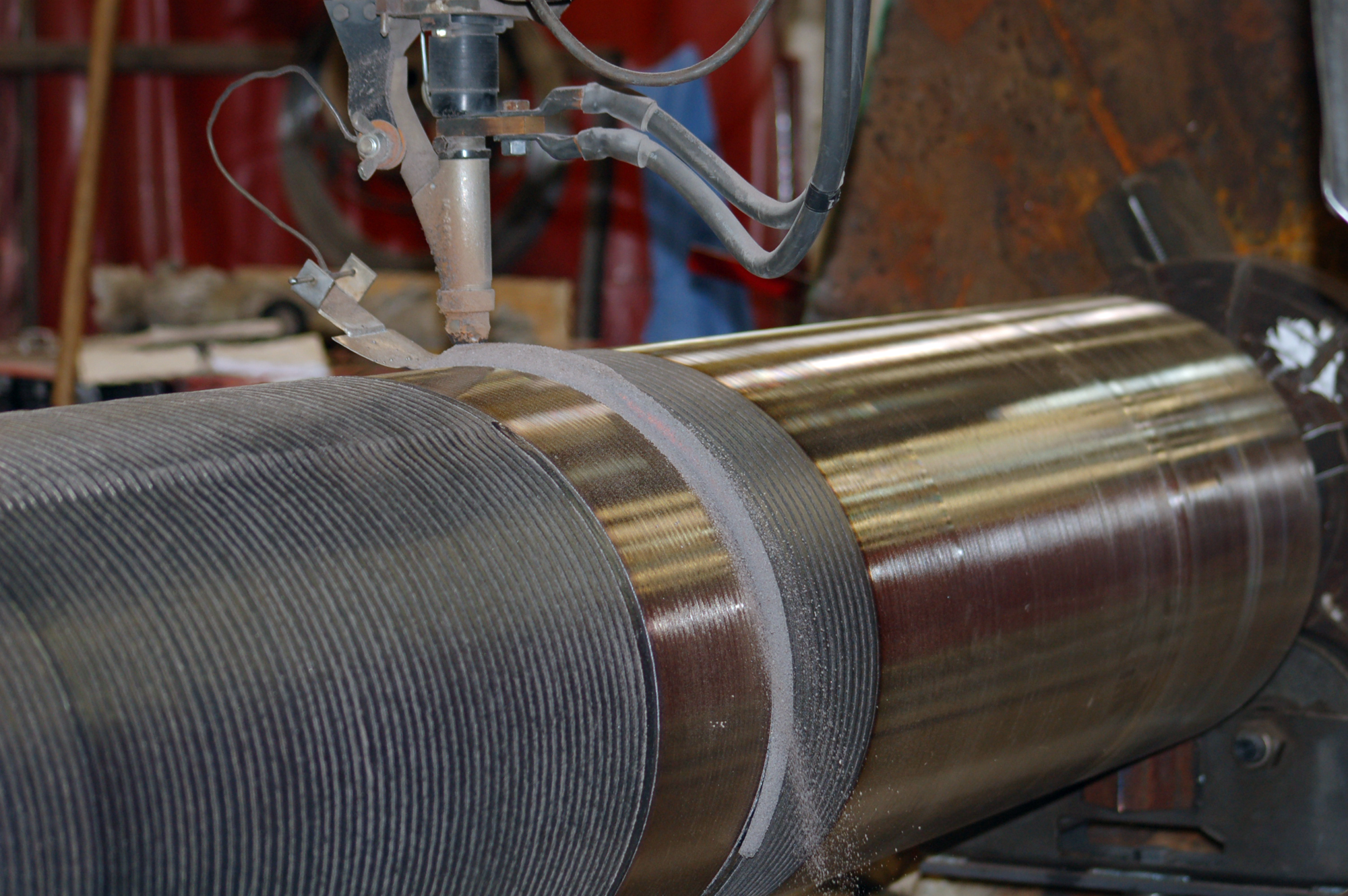

Tig Welding in Drum

Tig Welding in Drum

Harden Overlay

Portable Welding

We are mobile operators. When you need any kind of job in or around Vancouver/ Portland, you can count on us to be there with our fully equipped portable welding truck. Whether you need a repair to get your machinery back in action, or a job that needs to be done so that you can continue your project, you can rely on Diversified Welding Works for metal fabrication and onsite repairs. DWW has come to the rescue throughout the Pacific Northwest for emergency and scheduled shut downs for over 30 years.

Get A Quote Today

Only takes a few seconds!